DRI - Frequence series

The rotary feeder which associate cleaning and security

Conception:

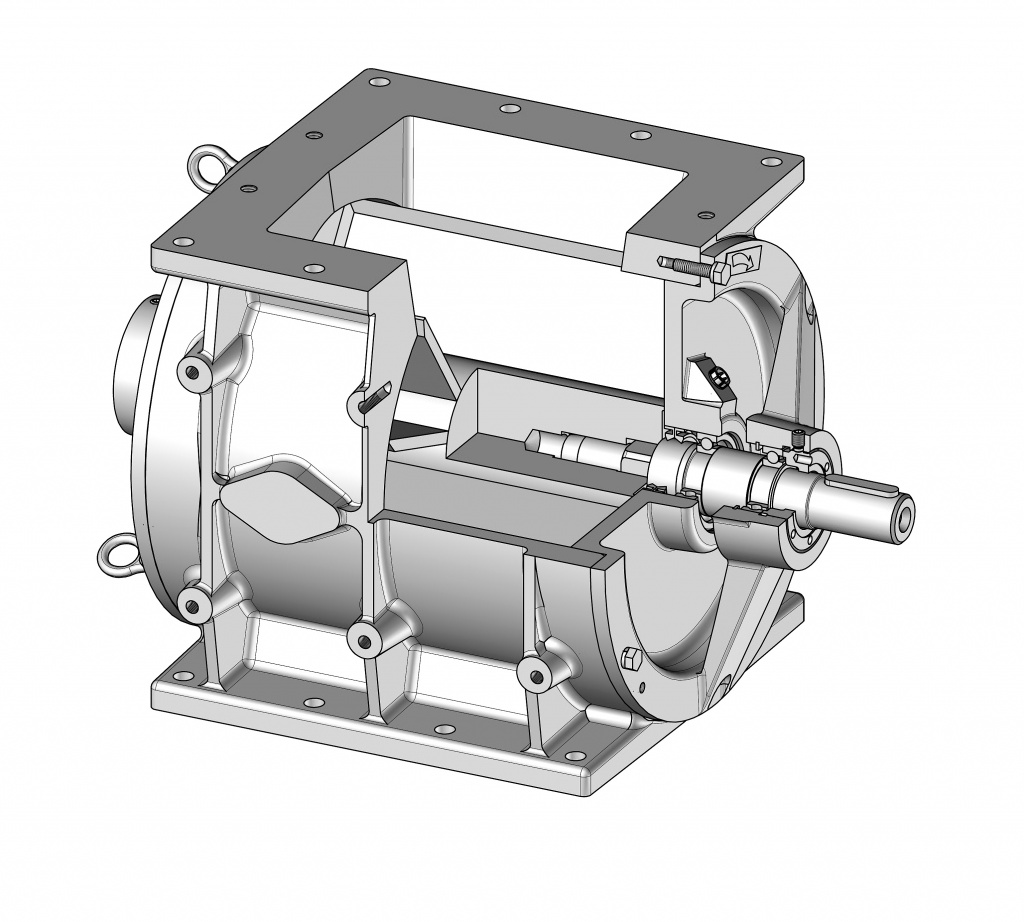

The DRI Frequence series was specially conceived for users needing to clean their installation very frequently. Many reasons can lead users to clean up their devices: hygiene, sticky products, multiple products passage… Due to its conception, the rotor can easily be extracted with ring screws (ensuring the shields closure when the device is functioning).

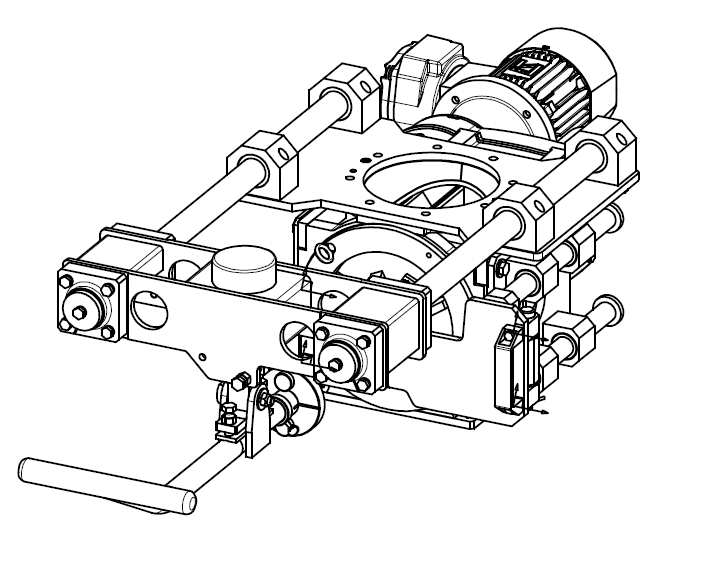

Due to the dismantling tooling help made of 2 guidance rails and a lifting trolley, the rotor manipulation is way easier. The end cover can also be mounted on the guidance rail to avoid putting it on the ground and so prevent an eventual contamination.

Whatever its size or location, this security ensures the user of an effective cleaning. Since no drop are possible, there is no risk of injury when cleaning. Its speed and easy manutention make this device to be an ally for maintenance services that need effective material. Its guidance and maintenance have been studied not to create any disruption after every extraction. The device adjustments remain the same as when it left our factory.

Different motorisation type can be mounted on your device on your request or according to our recommendations. On request, multiple combinations are possible and depending on the technical specification.

Application:

- Extraction

- Dosing powders/ granulates

- Flow regulation

- Introduce in pneumatic conveying

See differents possible applications here: https://www.acett.eu/en/ecluses-distributeurs-rotatifs.html

Depending on the product characteristics to transport, the DRI device would suit many lines of business such as chemical and pharmaceutical industry, petfood, cement, sawmil and wood indutry, biomass, minerals, steelworks, treatment of NHIW…

As for all the devices we provide, if your installation requires particular dimensions, we can always design and conceive a customized model or realize some adaptations on an already existing model.